Detection sensors based on optical, magnetic, inductive or capacitive principles of operation ensure accurate detection of different objects. Detection sensors have many applications, from presence and position detection to continuous condition monitoring and the detection of colors and contrasts. Thanks to the ASIC and LED technologies, they offer high reliability. Additional sensor information, such as data on vibration, shock, temperature, or sensor contamination, can be used via IO-Link to simplify modern production processes.

Proximity Sensors

Proximity Sensors

Millions of inductive proximity sensors are currently in use in virtually all industries. They detect metal objects without contact, and are characterized by a long service life and extreme ruggedness. With the latest ASIC technology, SICK's sensors offer the ultimate in precision and reliability. SICK can provide the right solution to meet your requirements every time – from cylindrical or rectangular standard sensors with single, double or triple operating distance, to special sensors for explosive zones and harsh environments. Our sensors are the intelligent, reliable route to implementing industry-specific and customized solutions to any task involving automation.

Photoelectric Sensors

Photoelectric Sensors

SICK’s sensor portfolio includes numerous photoelectric sensors for industry automation. The opto-electronic sensors are used both in simple and complex applications. Thanks to powerful technologies, they can even solve demanding detection tasks precisely. The sensors from SICK are being continuously further developed, thereby constantly opening up new fields of application. The resultant application flexibility is supplemented by a user-friendly installation and operation of the opto-electronic sensors.

Fiber-optic sensors

Fiber-optic sensors

When installation space is extremely limited or the objects to be detected are tiny, fiber-optic sensors are the ideal solution. If it is necessary for even higher requirements to be fulfilled, such as sensing range, temperature resistance, material durability or a flexible mounting process, the intelligent combination of sensors and fiber-optic cables can provide the perfect solution. A wide range of fiber-optic cables with application-specific optical heads ensure that every need is met.

Fork sensors

Fork sensors

SICK fork sensors combine senders and receivers in a single housing, meaning that they can be adjusted quickly. Thanks to the precise, focused light beam and the high detection accuracy, the sensors also detect very minor light attentuation differences. Many different fork sizes, straightforward mounting, and exceptionally high ambient light immunity are just some of the advantages of these fork sensors.

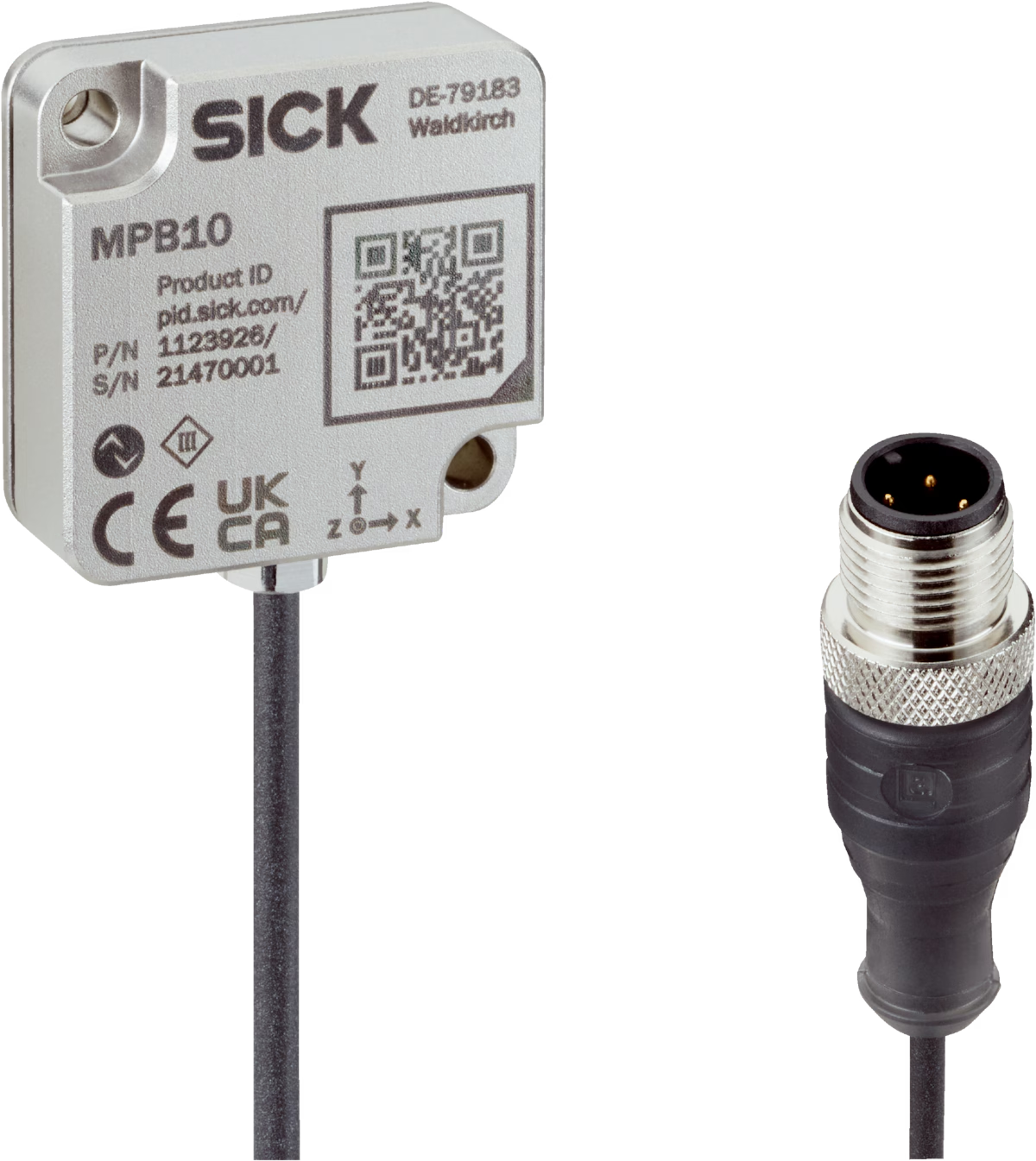

Condition Monitoring sensors

Condition Monitoring sensors

The Condition Monitoring sensors from SICK allow intelligent condition-based monitoring. They determine relevant physical parameters for mission-critical processes and applications. The sensor data provide the foundation for analyses that make condition-dependent maintenance possible. Besides reducing unplanned downtimes, they can thereby also increase the service life of components and reduce costs.

Color sensors

Color sensors

Color sensors detect object colors. To do so, the sensors emit light throughout the entire visible range onto the objects to be inspected, calculate the color proportions from the reflected light and compare these with previously taught reference color values.

Contrast sensors

Contrast sensors

Contrast sensors are primarily used in packaging/printing machines for the detection of printed or control marks. SICK's line of KT contrast sensors detects even the smallest contrasts at the highest speeds, such as print marks on foils or packaging. They detect minute grayscale variations between the mark and the background on matte, shiny or transparent surfaces. A variety of device types with different contrast resolution methods and teach-in versions are available to meet wide-ranging requirements.