We specialise in delivering advanced process automation solutions that integrate cutting-edge technologies like PLC (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and DCS (Distributed Control Systems). These systems enable seamless control, monitoring, and optimization of industrial processes, enhancing operational efficiency, reducing downtime, and improving system performance.

Ensure Product Quality

We measurement stability and hardware reliability ensures you have confidence in every product you ship.

Minimise Downtime

Asset management and data analytics solutions keep productivity at the highest level.

Accelerate Innovation

Hardware and software platforms are reconfigurable, providing maximum flexibility for future changes

Lower Cost of Test

Hardware lowers your total cost of ownership with fast test speed, excellent uptime, increased test coverage, and competitive capital cost.

Erection and commission support

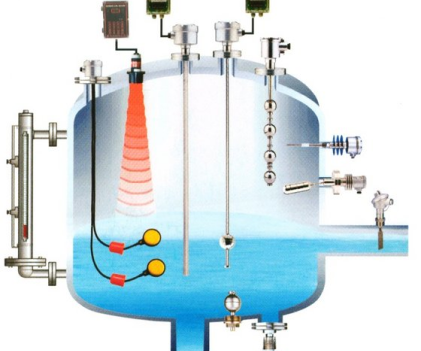

We provide comprehensive support for erection and commissioning, ensuring precise installation and configuration of key automation components such as sensors, actuators, PID controllers, and network communication systems like PROFINET and Modbus TCP/IP. ensures the integration of hardware with control systems is smooth, calibrated, and tested to meet your operational demands.

Process Monitoring (Live)

Using real-time data acquisition systems (RTDAS) and edge computing, our live process monitoring solutions provide instantaneous feedback on critical parameters such as pressure, temperature, flow rate, and machine performance. This continuous monitoring enables immediate identification of anomalies, enhancing process reliability and efficiency.

Remote Process Monitoring

Leveraging IIoT (Industrial Internet of Things) and cloud-based platforms,Remote process monitoring allows operators to manage and supervise production from any location. With real-time data streaming via secure protocols like MQTT or OPC UA, remote monitoring provides visibility into production without the need for physical presence on-site, supporting predictive maintenance and fast decision-making.

Performance Matrix

Our performance matrix utilises KPI (Key Performance Indicators) such as OEE (Overall Equipment Effectiveness), MTTR (Mean Time to Repair), and MTBF (Mean Time Between Failures). These metrics are tracked through data logging and historical data analysis, giving operators a comprehensive understanding of their system's productivity, energy efficiency, and areas for potential optimization.

Alarm Management

Our alarm management system, integrated with SCADA and DCS platforms, provides real-time alerts for critical process deviations. Utilising advanced algorithms such as deadband filtering and event correlation, it minimises nuisance alarms while ensuring that critical warnings—such as equipment overloads, temperature thresholds, or pressure spikes—are prioritised for immediate attention.